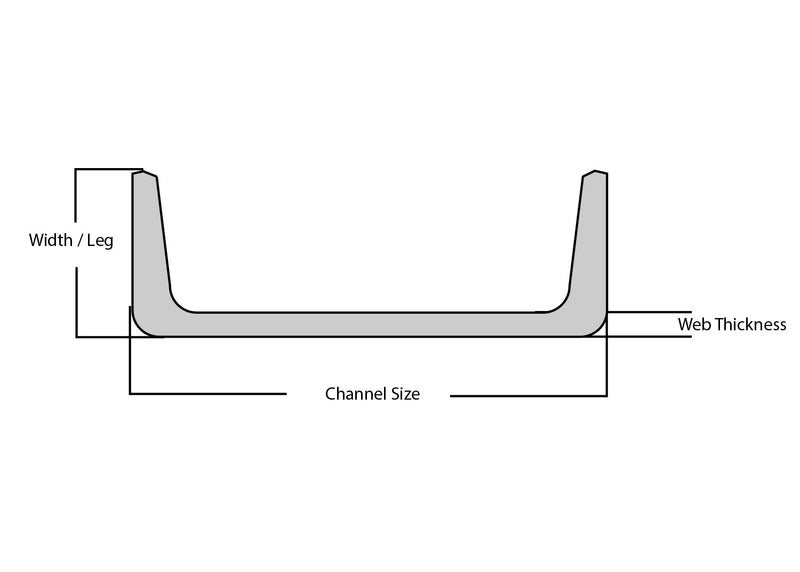

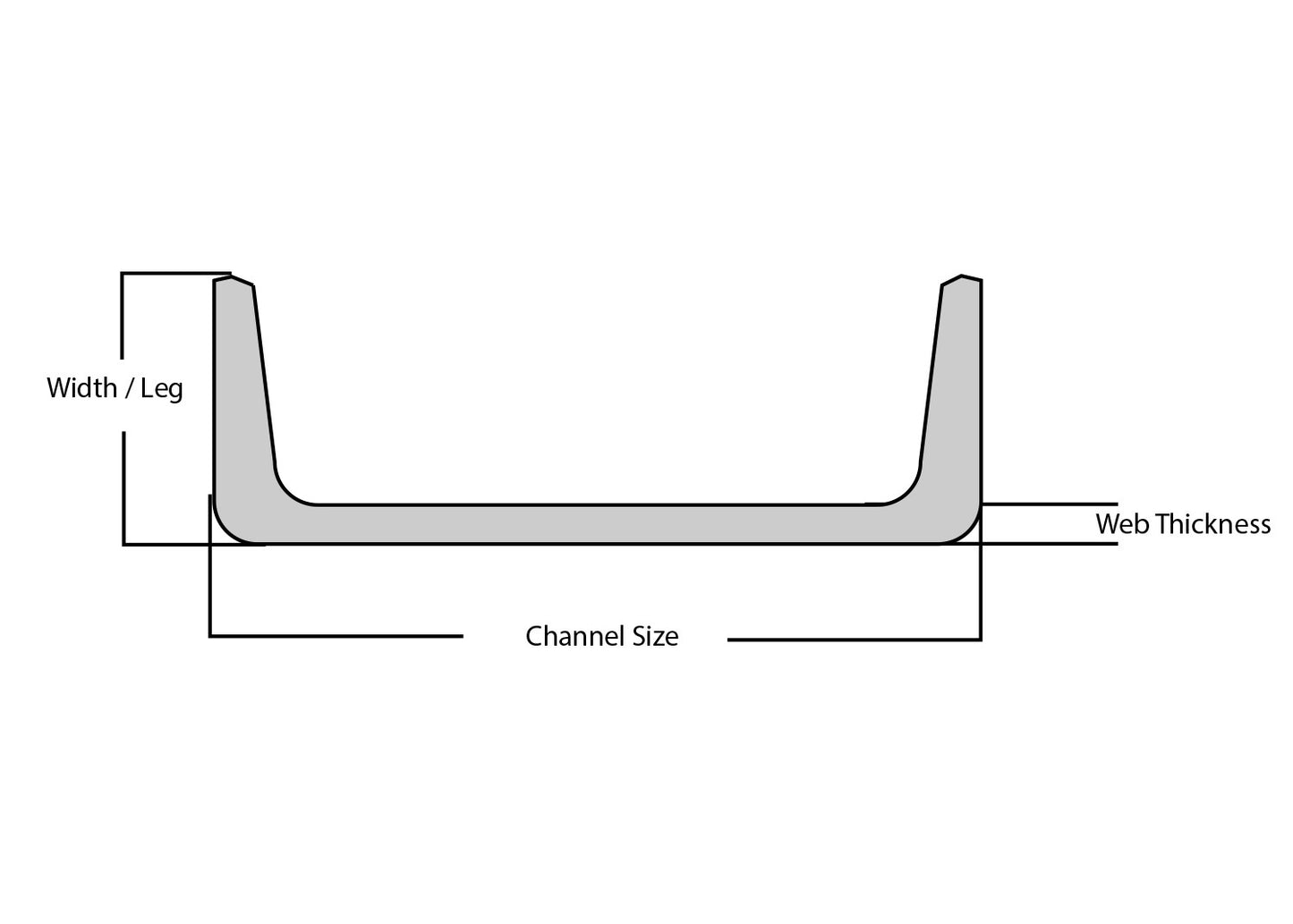

Steel Channel is a hot rolled, mild steel structural C shape with inside radius corners that is ideal for all structural applications, general fabrication, manufacturing and repairs. Steel Channel is widely used in industrial maintenance, agricultural implements, transportation equipment, truck beds, trailers, etc. Its C-shape or U-shape configuration is ideal for for added strength and rigidity over steel angle when your project's load is vertically or horizontal. This steel shape is easy to weld, cut, form and machine with the proper equipment and knowledge. In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes. Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (I-beams, angle stock, channel stock, and so on), bar stock, and rails. Most steel mills have rolling mill divisions that convert the semi-finished casting products into finished products.