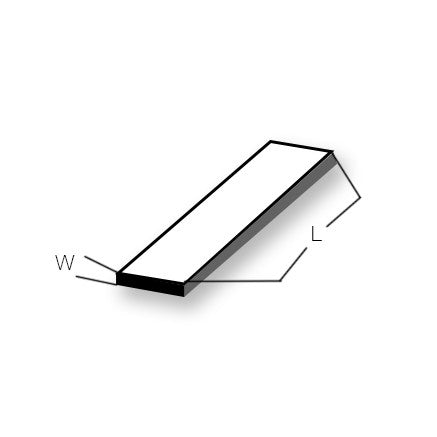

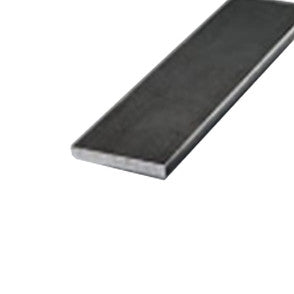

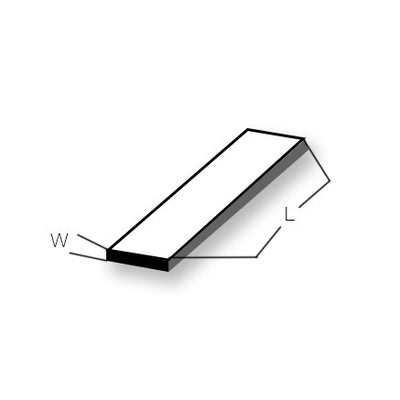

Hot-Roll Flat Bar 1-1/2" x 4"

Couldn't load pickup availability

Flat bars are a flat, rectangular section with square edges varying in sizes. This cost-effective steel product is suitable for a wide variety of applications and is distributed into the construction, engineering, manufacturing, mining, grating, fabrication and many other industries. The flat bar's versatility is the main reason it is usable throughout various industries, along with the excellent strength and formability combination of steel. In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its re-crystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its re-crystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes. Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (I-beams, angle stock, channel stock, and so on), bar stock, and rails. Most steel mills have rolling mill divisions that convert the semi-finished casting products into finished products.